Oven Modifications & Rebuilds

When process requirements change, older ovens can be modified or rebuilt to meet current design standards and increase throughput or efficiency. Changes include new conveyors, increased energy efficiency, longer dwell times in the heat zones and new controls. HeatTek will transform the equipment to “like new” conditions providing additional years of service at a comparatively lower cost.

Support Equipment and Services

HeatTek offers complete turnkey systems. Other products and equipment offered with our systems include:

- Fire Protection Systems

- Ambient Air Cooling systems

- Chilled Air Cooling Systems

- Installation

- Startup Service

- Preventative Maintenance Service

- Spare parts

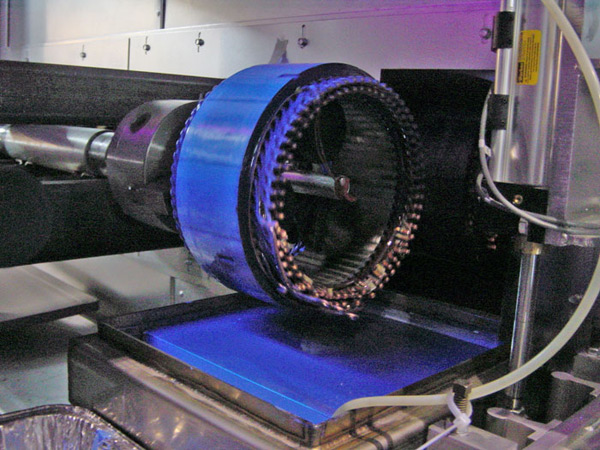

Roll Coating Conveyor Oven Spare Parts

We provide aftermarket services and spare parts for all roll coating conveyor ovens. We offer a reliable source of high-quality replacement parts and components for roll coating conveyor ovens manufactured by HeatTek and other manufacturers. Through our extensive industry experience, we understand the importance of repairing your equipment as fast as possible to minimize production downtown and our dedicated spare parts team is ready to help you.

Types of Spare Parts include:

- Combustion components: burners, flame rods, regulators, igniters, and pressure switches.

- Conveyors, chains, fixtures, and tooling

- Electrical components: fuses, relays, switches, and controllers.

- Drives, motors, and transmissions.

- Fans, blowers, and air kits.

- Pumps, valves, nozzles, and pipe fittings.

- Insulated panels, and insulation.