Electric Motor Powder Coating Applications

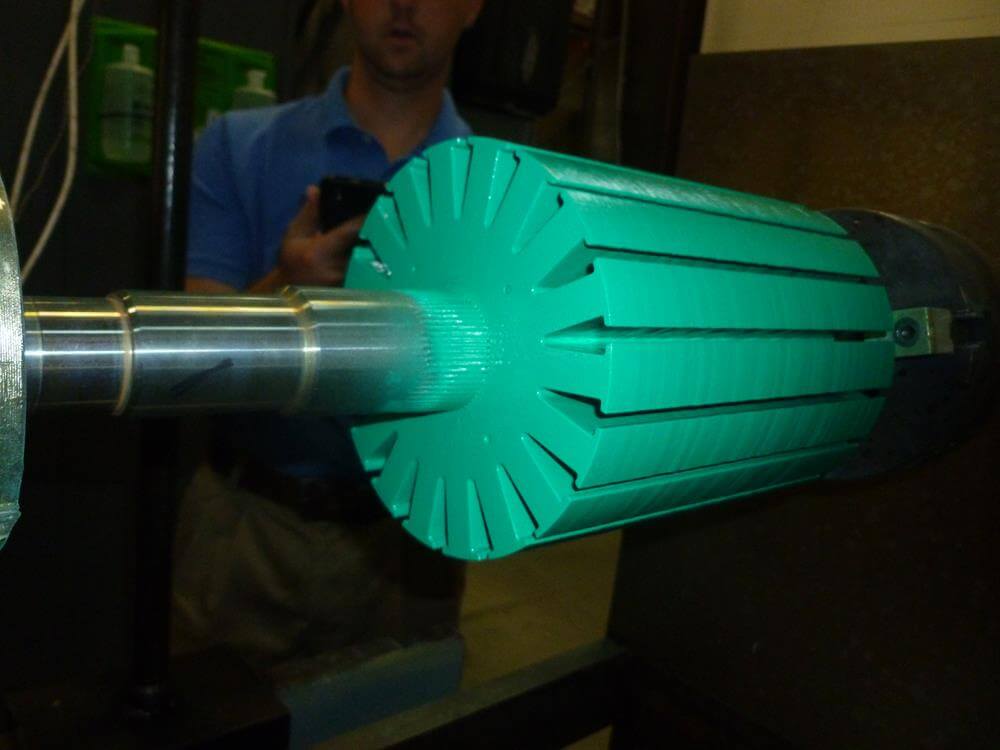

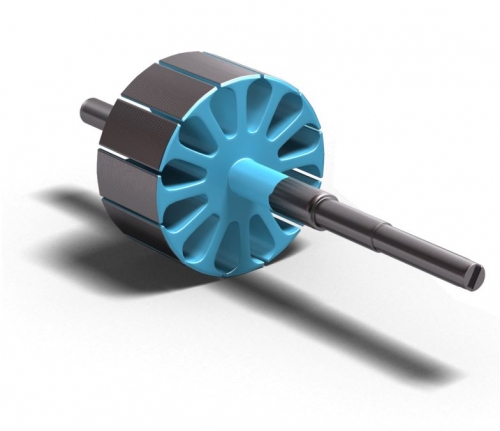

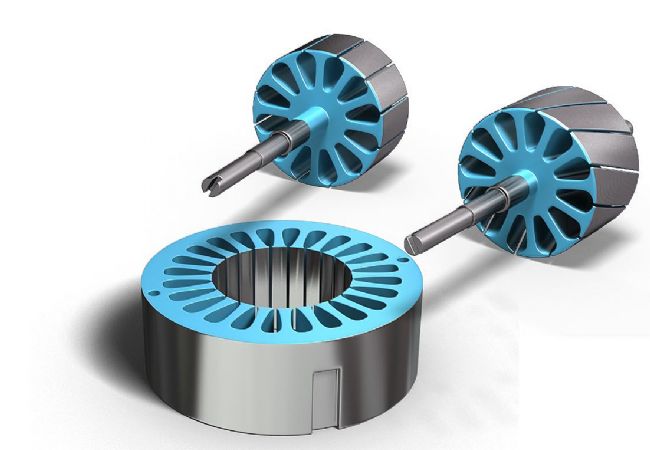

For Industrial motor applications, HeatTek powder coat systems apply an epoxy powder that is designed to protect and insulate unwound cores from hi-pot failures giving you the electrical protection required for your parts. Coatings are applied to smaller armatures most often by electrostatically charging the parts prior to exposing the parts to the powder. Larger rotors are preheated and the roll is coated in a fluidized bed for a short time based on the desired film build.

About HeatTek’s Powder Coat Systems

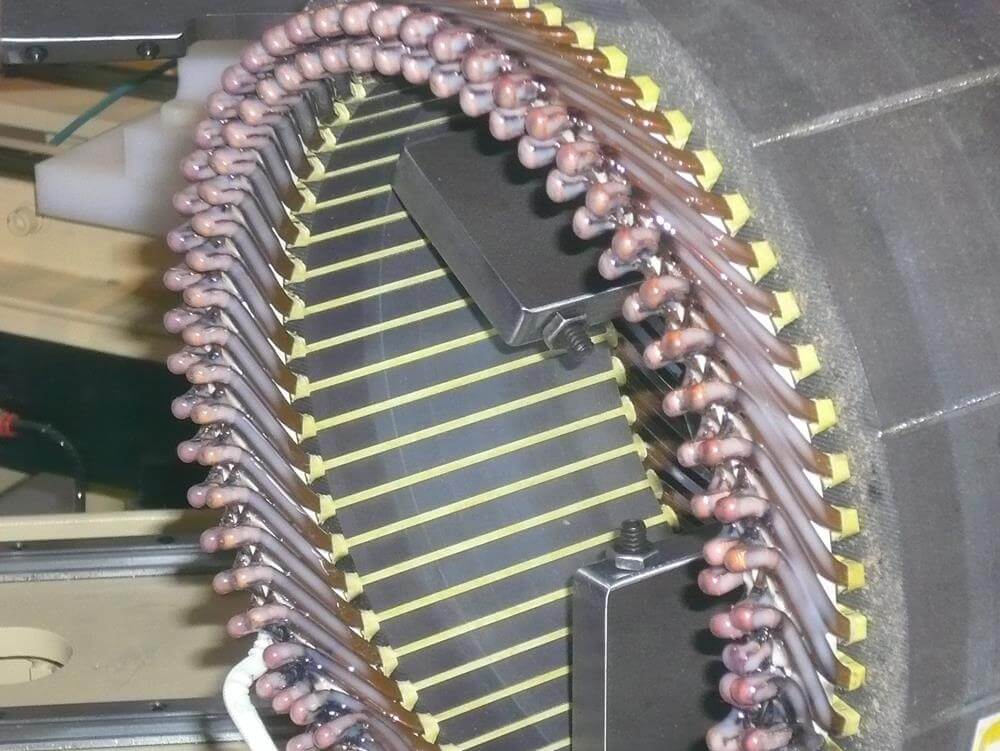

HeatTek is the industry leader in stator powder coat systems used in electric/hybrid generator stators. Stator powder coat systems are typically the final step in the winding process. Parts are dipped into a fluidized bed past the welded wire connections. Cured epoxy provides critical strength to the welded ends of the rectangular wire for optimal performance and durability in the finished assembly. HeatTek works closely with epoxy powder suppliers using their published recommendations in developing the exact coating process for each system. Typical coating systems may include the part handling conveyor, preheating and curing systems, powder aeration and delivery equipment as well as fluidized powder beds. HeatTek’s experience in heating systems allows us to choose the optimal method of heating the part based on part size and production volumes. Heating systems include induction, resistance, infrared, and convection heating methods.

Electric Motor Powder Coating System Spare Parts

We provide aftermarket services and spare parts for all industrial powder-coating ovens. We offer a reliable source of high-quality replacement parts and components for industrial powder coating ovens manufactured by HeatTek and other manufacturers. Through our extensive industry experience, we understand the importance of repairing your equipment as fast as possible to minimize production downtown and our dedicated spare parts team is ready to help you.

Types of Spare Parts include:

- Combustion components: burners, flame rods, regulators, igniters, and pressure switches.

- Conveyors, chains, fixtures, and tooling

- Electrical components: fuses, relays, switches, and controllers.

- Drives, motors, and transmissions.

- Fans, blowers, and air kits.

- Pumps, valves, nozzles, and pipe fittings.

- Insulated panels, and insulation.

Contact HeatTek with your coating system requirements today.