Infrared Heating Systems

Infrared (IR) heating uses various wavelength light emitter panels to radiate energy based on the intensity of the heating required for the parts being processed. IR panels used can be made from sheathed elements, quartz panels, or lights to UV wavelength lamps. The use of IR heaters is ideal when the radiant light energy can reach the part surface.

An advantage of IR heating is it’s often faster than convection heating if only surface heating of the part is required.

Infrared heating can be used in curing powder paint, epoxy, and polyester resin. In addition, it can also be used to pretreat other types of coatings.

HeatTek utilizes infrared heaters that are specific to an individual system. These heaters can be used across a variety of industries, with an additional offer of services to fit your heat treatment needs.

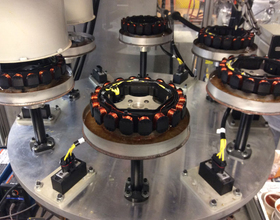

Induction Heating Systems

Induction heating uses electromagnetism to heat the conductive components of a part. Induction heating is accomplished by running an electric current through an induction coil which produces an electromagnetic field. When steel or iron components are placed within that field, they resist the electrical flow, creating energy and heat in the process.

Induction heating can be a very effective and efficient use of energy and quickly heat up components, however, the products need to be shaped so that a coil can apply the power properly. When used during a preheating or post-heating process, it can dramatically cut down production times, allowing for greater efficiency and product throughput.

Our induction heating systems are custom engineered and manufactured to meet your specific needs. These systems are customized by project specifications, and if you have any older oven systems, they can be modified and rebuilt with our services.

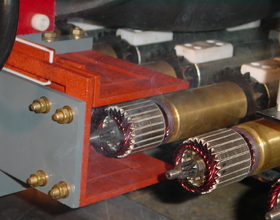

Resistance Power Heating Systems

Resistance heating is the direct heating of a part or product that can have power applied to it. Examples of resistance heating are electric motors and transformers that allow the part to act as a resistor. Applying various amounts of power to the part based on its resistance will determine the amount of time it will take to heat a part by this method. Resistance heating in electric motor applications is somewhat the opposite of induction heating where the conductive steel is heated. In resistance heating, most often the copper winding is what is directly heated, which then conducts the heat to other parts of the product that are in contact with it.

Combinations of Heating Methods

HeatTek can engineer custom heating systems as an industrial oven manufacturer, including furnaces, industrial ovens, and other thermal systems, with any of these technologies, either on their own or in combination for reduced heating times and optimal processing times. To learn more about the services we provide, call HeatTek today.

Heating Method Types

Convection Air Heating Systems

The convection heating principle is based on the principle of moving hot air past a part or object at a velocity that allows transfer of the heated air to the part.

View More

Induction Heating Systems

HeatTek custom induction heating systems & equipment operate by placing a conductive part inside or near an induction coil

View More

Infrared Heating Systems

HeatTek industrial infrared heaters utilize various types and styles of wavelength emitters for each specific system, including quartz emitters, among others.

View More

Resistance Power Heating Systems

We at HeatTek specialize in custom manufactured, resistance heating systems, which we build to fit your unique job applications

View More